NCA's Activities for Environmental Conservation

CO2 Emission Reduction Efforts at Facilities

Be Committed in Local Communities

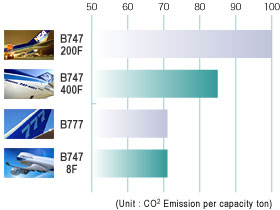

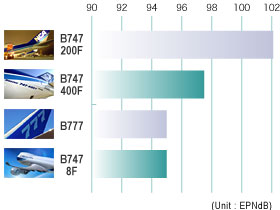

All the aircraft that NCA operates by itself are state-of-the-art cargo aircraft, Boeing 747-8 airplanes, which emit less CO2 than earlier aircraft. It is committed to effectively using fuel and efficiently transporting cargos in order to reduce CO2 emissions.

1. Replace Aircraft and Engines

Advanced Cargo Aircraft

NCA was the world’s first airline to place an order for Boeing 747-8 freighters, state-of-the-art aircraft, to replace Boeing 747-400 freighters. It received the first aircraft on July 25, 2012. The aircraft has greater cargo capacity and range than the 747-400 freighter. They are equipped with GEnx engine, General Electric (GE)’s world-leading engine. As environmentally friendly aircraft, they very quietly operate and emit less CO2. Since 2019, NCA has completely replaced its earlier aircraft with Boeing 747-8 freighters in order to reduce its environmental footprint.

|

|

2. Reduce Aircraft Weights and Fuel Consumption on the Ground

Reduce weight of Unit Load Device Containers

| Cargos are loaded into metal containers known as unit load device (ULD) before they are loaded onto an aircraft. In order to effectively save fuel, NCA uses “pallets,” constructed with lightweight metal alloy plates to reduce the weight of the loaded aircraft. NCA closely consulted the manufacturer about whether any attempt to reduce the weight might compromise the strength of ULD. The pallet is approximately 15% lighter than a conventional ULD container. The saved pallet weight may usefully provide additional capacity to carry cargoes. |  |

※ULD (Unit Loaded Device)

It is a general term for cargo shipping containers, loaded on aircraft. ULDs come in two forms; containers and pallets. Containers are box-shaped and pallets are plate-shaped. In addition to the lightweight pallets mentioned here, NCA offers a variety of ULDs to meet customers’ specific shipping needs.

Link : Home > Service > Aircarct and Unit > ULD (Unit Load Device)

Clean the Inside of the Engine

As aircraft operate, deposited dust and dirt build up on the compressors, which transfer air to the combustion chamber of the engines, and compromise the combustion efficiency of engines. As a result, engines consume more jet fuel. NCA uses warm water to wash the inside of the engine and remove the dirt. The maintenance restores engine combustion efficiency, improves fuel consumption and reduces CO2 emissions. Since the engines work efficiently, its workload is reduced, and related maintenance activities, including replacement of parts, are reduced.

※The rainwater is stored in the hangar and provides useful resource for washing engines.

Prioritize Ground Power Supply for Parked Aircraft

During flight, an aircraft uses electric power provided by electric generators attached to the aircraft engines. After the aircraft arrives at its destination airport and the engines are turned off, electric power is still needed for lighting inside the aircraft or other use. Aircraft are equipped with auxiliary power units (APUs), which use aircraft fuel to produce electric power. The devices may be used after the engines are stopped to meet lighting and air conditioning need inside the aircraft. Another power supply known as ground power unit (GPU), which is available s on the ground, however, may save aircraft fuel and reduce CO2 emissions and noise. We push for the use of the ground power source.

※APU (Auxiliary Power Unit)

Auxiliary power unit is installed in an aircraft and provides power source to start up the main engine and operate air conditioning and electrical systems. Since it runs on jet fuel, the device has less energy efficiency than ground counterparts. You can save jet fuel equivalent to approximately 1.5 drums (300 liters) of fuel and reduce CO2 emissions by approximately 0.7 tons by withholding use of APU for one hour.

※2 GPU (Ground Power Unit)

The equipment supplies electrical power to the aircraft from ground to operate air conditioning and other power systems. There are mobile (truck-mounted) and installed types available.

3. Efficient Operation System

Implement more Efficient Flight Technique

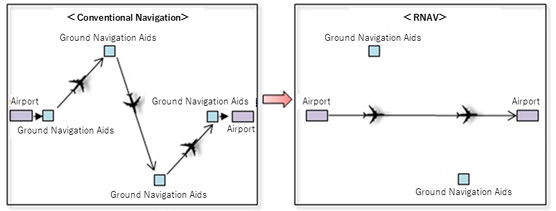

Earlier, airways or air routes between departure and destination airports were planned in a manner to go through radiofrequency ground stations. The flight lines, therefore, often followed polygonal patterns and resulted in less efficient air routes. Recently, NCA implemented RNAV (aRea NAVigation) operation system, which draws on global positioning system-based satellite and inertial navigation systems to locate aircraft and develop straightforward routes from their positions to any destinations. RNAV system allows aircraft to find more efficient routes to their destinations and alternative routes. Shorter flight times and distances contribute to less fuel consumption and CO2 emissions.

Improve Descent and Approach Techniques

Delayed flap and landing gear operation is among the flight techniques developed to reduce noise during landing. According to the technique, the elevators (flaps) and wheels (gears) are lowered later than usual when the aircraft is expected to safely approach. The practice reduces air resistance that the aircraft experiences and minimizes engine thrust during descent. It also reduces noise, fuel consumption and CO2 emissions.

Explore Additional Flight Routes

Eligible flight routes are predetermined for specific scheduled flights, depending on the countries and regions and other restraining factors. NCA, however, always explores the shortest airways between the departure and destination airports as long as they are acceptable in the light of the restraining factors.

Optimize center of gravity

A cargo aircraft (Boeing 747-8 freighter) carries up to 34 cargo containers (ULDs) in the segment that corresponds to the space where passenger seats are installed in a passenger aircraft (main deck) and up to 32 ULDs in a space below the main deck (lower deck). ULDs contain various cargoes consigned by our customers, so their overall weights vary. The position of their collective center of gravity in an aircraft has impact on fuel consumption during flight. NCA carefully optimizes the relative position in order to reduce fuel consumption.